- October 4, 2022

- Posted by: Andrew

- Category: Uncategorized

Perhaps the most common sewing problem is correct sewing machine tension. Thread tension means the amount of thread that can be fed into the machine to create a stitch. The more threads in the stitch, the looser the stitch. The less thread, the tighter the seam.

The dial controls the upper thread tension on the sewing machine thread path. So when threading the machine, ensure the thread is properly placed between the tension discs. Otherwise, the machine will not sew properly. When the sewing foot is raised, the tension disc is open, and the needle thread is not tensioned. However, if you lift your foot when threading the machine, it will be easier for the thread to enter between the discs. Thread tension is a very important topic, but it is so often misunderstood that I include it in my beginner sewing classes.

Adjusting the sewing machine tension

A sewing machine needs a top and a bobbin thread to create a properly shaped stitch. These threads must work in harmony with each other so that they mesh precisely in the middle of the fabric. Any imbalance will cause one to pull the other to the opposite side of the weave. This results in poor-quality stitches that may not last long.

The bobbin thread tension is the factory setting and is normally not adjusted during normal sewing. Since the upper thread tension is usually adjusted, only the upper thread tension is explained here. The dial has a setting range of 0 to 9, with 4.5 being the “normal” position for regular straight stitches. This should work for most fabrics.

If you sew wide stitches such as zigzag stitches, the bobbin thread may be pulled. It may be visible on the side of the stitching, slightly raised, or shrunk in the fabric. If you see this, relax a bit (perhaps between 3 and 4). After that, the dough will become flattered. If you’re top stitching and want your stitches to be more visible, it also helps to loosen the top tension a bit. Tension settings will vary slightly from machine to machine. The thickness of the thread and the weight of the fabric also affect the tension. So don’t be afraid to do experiment and find the best settings for your particular project.

How to check the thread tension

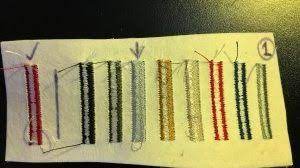

It can be difficult to tell what is wrong with the tension on your sewing machine. This makes it easier to diagnose machine tension problems when threading different colors on the top and bottom.

Upper tension too loose (or lower tension too tight)

The upper thread tension is too loose, and the upper thread is pulled down

If the thread is too loose, it will not connect to its fabric counterpart and the stitch will not form properly. In the image above, the bobbin thread rests on top of the fabric rather than being pulled into it. The bobbin thread may come off.

Bobbin thread tension

If there is a dip in the coil, there is no need to change the under voltage. Unless you change it yourself, it is highly unlikely that the factory settings have been changed. To do this, the needle plate must be removed so that the bobbin case can be removed. Then access the coil tension screw.

If you’re using a front-loading spool with its own removable bobbin case, there’s a good chance that the screw will be moved – even by accident. Therefore, it will not be the factory default settings. Put the bobbin in the case and check the tension. All you have to do is hold the thread over it and ensure the bobbin case does not move. The tension is good if the thread is slightly pulled and the bobbin case is slightly out of alignment. If it falls freely, it is too loose. If it doesn’t move at all, it’s too tight.

To adjust the under tension, you’ll need the small screwdriver that came with your sewing machine, as a small screw on the bobbin case controls everything. Turn clockwise to tighten, counterclockwise to loosen (right to tighten, left to loosen).

When embroidering with the free sewing machine, you can obtain a stimulating effect by setting the sewing machine tension between tight and loose. If you don’t understand how the tension of each thread affects the others, consider attending a free motion embroidery workshop where you’ll learn a lot about how to use a sewing machine.