- October 17, 2022

- Posted by: Andrew

- Category: Uncategorized

Chenille is described, French for caterpillar or fuzzy caterpillar, as “a soft, tufted silk, cotton, or worsted yarn used for embroidery or fringing.” In North America, chenille is sewn onto letter man jackets. It is most commonly recognized as an emblem or lettering that can be Historical. Chenille had several uses in fashion and home furnishings, from delicate lacework to the bold look of school mascots. Chenille is a type of embroidery most of us are familiar with delicate chain stitch lace.

Traditional School Mascot Moss Chain

Originally hand-sewn, chenille production was industrialized about 20 years after the lockstitch sewing machine’s patent. A French engineer named Bonnaz invented his first chenille sewing machine in 1866, and soon after, he joined his Cornelly Company to manufacture and sell his inventions. Years later, Singer received a US patent. There are a few design changes from the original machine. Some models have added braids and cords, but the basic machine has remained the same for over 100 years.

Today, manual chenille looms are manufactured by many machine manufacturers. Experienced operators often use these machines.

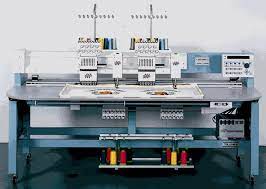

Chenille embroidery Machines

Chenille embroidery machines usually produce both chenille stitches, purl stitches, and chain stitches. Using a hook needle that pulls away the thread through a looper below the stitch plate, as opposed to a standard sewing machine needle with a threader, chenille sewing machines are commonly used for both moss and warp types. Use only one thread for stitching.

A chenille embroidery machine usually produces two stitch constructions: the slip stitch, the purl stitch, and the chain stitch. Moss stitch is most commonly used to fill in areas and add depth, while chain stitch is used for contours and monograms and can be used to create a more subtle look. A wide variety of thread and needle sizes can be used to create very different looks on and now electronic machines.

Cornelly and other manual chenille loom makers have developed a variety of machines based on the original design. A sewing machine for wallpapers, cords, sequins, and a 2-needle sewing machine for sewing with four threads!

Chenille bedspreads and bathrobes are made on the same principle as chenille embroidery. Like many carpets, the material is made on special looms. The chenille was made on a Schiffli machine with a specially designed attachment and no spool. Other Schiffli attachments also produce cut chenille.

Variations of chenille are created on his multi-head machine with special attachments and slub yarns.

Other Variations

Yet another variation of the chenille look is created on various lockstitch machines by sewing looped threads or cords using a special attachment commonly known as Omni stitch. Tajima offers his KB-2M attachment for creating loops on a standard lockstitch embroidery machine.

There are various ways to create a look similar to chenille, but embroidery is not true chenille. Genuine chenille embroidery is made with closed loops in a moss stitch format. In this case, continuous threads are worked into the material and set into loops or piles.

A chenille embroidery machine usually produces two stitch constructions: the slip stitch, the purl stitch, and the chain stitch. Moss stitch is most commonly used to fill in areas and add depth, while chain stitch is used for contours and monograms and can be used to create a subtler look. A wide variety of thread and needle sizes can be used to create very different looks on and now electronic machines.

Cornelly and other manual chenille loom makers have developed a variety of machines based on the original design. A sewing machine for wallpapers, cords, sequins, and a 2-needle sewing machine for sewing with four threads!

Schiffli machine

Chenille bedspreads and bathrobes are made on the same principle as chenille embroidery.

Like many carpets, the material is made on special looms. The chenille was made on a Schiffli machine with a specially designed attachment and no spool. Other Schiffli attachments also produce cut chenille.

Variations of chenille are created on his multi-head machine with special attachments and slub yarns.

Yet another variation of the chenille look is created on various lock stitch machines by sewing a looped thread or cord using a special attachment commonly known as Omni stitch. Tajima offers his KB-2M attachment for creating loops on a standard lock stitch embroidery machine.

There are various ways to create a look similar to chenille, but embroidery is not true chenille. Genuine chenille embroidery is made with closed loops in a moss stitch format. In this case, continuous threads are worked into the material and set into loops or piles.

Software and electronics developed for the chenille market only mean one thing. It means that more and more consumers will seek out this kind of work in local embroidery. The market will continue to grow as the public becomes more familiar with chenille in their daily lives.

Manufacturers like Tajima continue to develop and improve their products to help embroiderers meet their customers’ needs. Tajima is a cording and gluing device for chenille looms controlled by electronic devices. We continue to lead the embroidery industry with innovative options such as genuine chenille looms and software designed to produce beautiful chenille work.